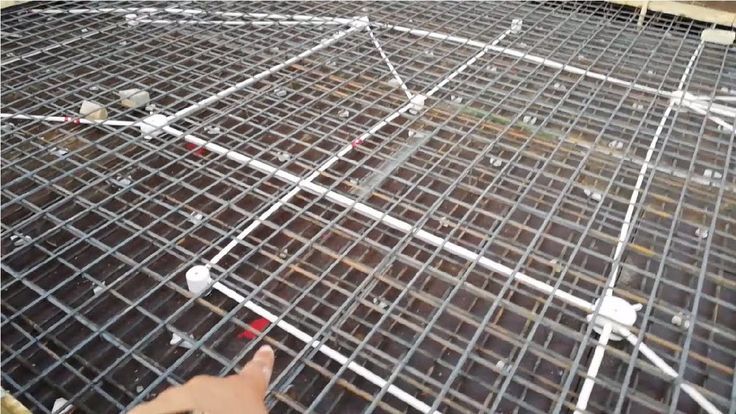

When your home’s slab (lenter) is being cast, the electrician will lay electrical pipes into the concrete, as shown in the process above. It’s crucial to ensure the quality of these pipes, as poor-quality materials can cause long-term issues. Here’s what you need to know to make the right decision:

1. Choose the Right Pipe Bundle

Ask your electrician to use a bundle weighing 12 to 15 kilograms. These bundles are sturdy enough to withstand the weight and pressure during slab casting. Lightweight pipes might seem sufficient, but they are prone to breakage under stress.

2. Why Sturdiness Matters

- Manual Concrete Work: If the concrete is poured manually over the pipes, the added weight may break weaker pipes.

- Compromise on Functionality: Broken pipes allow cement to fill inside, blocking them and making them unusable.

By opting for sturdy pipes, you ensure the pipes remain intact even under heavy labor work or material pressure.

3. Check for ISI Mark

While ensuring the pipes are ISI-marked is essential, it’s no longer a complete guarantee of quality. Many products now bear the mark, so prioritize weight and sturdiness.

4. Why This Matters for Your Home

Poor piping during slab casting can lead to rewiring issues or even structural damage in the future. By investing in quality materials at this stage, you avoid unnecessary repairs and ensure a smoother electrical setup.

Pro Tip: Always inspect the materials yourself or consult a reliable professional before the work begins to ensure the right bundle and proper installation.